For some reason(s), diesel vehicles offered to the average consumer over the past 40 years have arrived for sale at local dealerships either woefully engineered and/or seriously de-tuned. Fortunately manufacturers have recognized the value and profit potential in diesel technology and the engineering has caught up. Diesel builders have also been required to keep pace with ever-tightening emissions standards levied by governments. That has led to a combination of significantly de-tuned engines saddled with in some cases, ridiculous amounts of overly complex emissions control gear.

The real state of just how bad it is came to the fore last year with what’s being called “VW Dieselgate.” Volkswagen engineers forced to resolve meeting emissions standards against onerous bean counters in their own company simply decided to use software to cheat the government regulators in probably the biggest scandal that’s ever hit the automotive industry. Restitution to dealers and customers is running in the billions and it’s not over yet. Volkswagen’s survival as a company was even in question at one point. Here is a good synopsis of the VW fiaso, as of Thanksgiving, 2016. It’s not over yet.

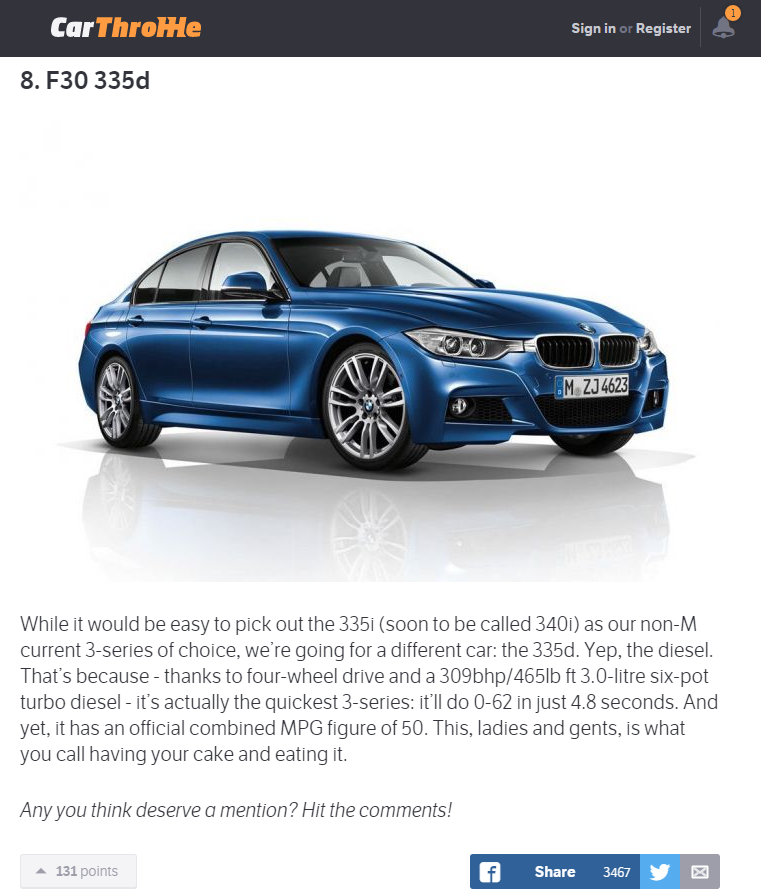

Well, I’m not gonna take it anymore, and I’m far from alone in that sentiment. As usually happens in cases like this, 3rd party software engineers and fabricators have stepped up to address the issue. Enthusiasts who love their cars and are willing to pay the price, have options to modify or eliminate troublesome, power-sapping pollution control systems in their cars. Bimmertime is upon us. I just returned from a friend’s place who helped me get the car finally done right. He has some 1st hand experience with the 335D, and spent a day demonstrating how to eliminate the remaining two emissions systems from the car: DPF and DEF. These contraptions have the ability to stop the car in it’s tracks, entailing thousands of dollars in repair expense when they do break – and they are proven failure-prone. The $40/gal LL04 low SAPS oil required to support the DPF is a real kick in the wallet, too. BMW took a beating in warranty outlays on this particular model here in the U.S. My car ended the extended warranty period last year with a total of a whopping $23k in warranty repairs – almost all emissions systems work.

We’ve seen in that previous post linked above how exhaust gas re-circulation and the crankcase vent combine to literally kill the engine by clogging the intake over time and what I did to correct those particular top-priority problems. That process was completed after we got the car back from BMW with an $8,000.00 bill (covered under warranty) for intake cleaning and new injectors. Finishing the job involved basically replacing the entire exhaust system along with an engine control computer coded to support a lack of the now-absent DPF and DEF systems. Here’s what came out and what went in:

Removing the DDE (Engine Control Computer) was probably the easiest part, despite involving quite a bit of disassembly to get to it. It’s hidden under two covers, and there are a few wires connected to it.

Old Exhaust New Exhaust

Installed

The car now returns even better fuel mileage, up by at least 2MPG, despite already being a star in that category. I snapped this dash readout upon arrival home after cruising the last 200 miles out of Kansas into Colorado, mostly gently upsloping terrain, no wind, 78mph (GPS-corrected) at 70F ~5,000 ft:

Last but not least, power is up nicely as well of course. Butt dyno says 350hp and 600 ft.lbs. It pulls HARD. I’ll guess mid 12’s properly setup for the quarter mile. I wanted to keep the exhaust sound on the quiet side of aftermarket, whatever that means to the listener. Some like it loud, I do not. This system suits my taste perfectly. The new mufflers are just slightly louder, producing a nice low growl at idle and a pleasing “woosh” under acceleration in normal driving. The only time I want to hear the engine note is during the wicked shriek it emits at full song on a highway kickdown – priceless!

The problem with diesel emissions technology is really quite simple: Fuel. The more fuel burned, the more emissions needing squelched. Gassers are similar in this respect, but to a lesser degree and for reasons involving the different types of emissions they produce. So the obvious, easiest and most effective means for manufacturers to start addressing the diesel emissions quandary is to limit fuel. Less fuel equals less power. My old Dodge truck is a perfect example. It’s Cummins 5.9 came from the factory rated at 165 horsepower and 425 foot-pounds of torque. Power output literally almost doubled overnight after a new set of bigger injectors and turbo with some injection pump mods. But it puffs black smoke on shift recovery and under heavy throttle until it gets up on the turbo. I suppose if everybody drove one all the time it might hasten the planet’s demise by some immeasurable amount. But they don’t, and it won’t.

Government regulators would do well to focus more on commercial and corporate entities that actually produce a lot of pollution. I want my diesels to pull like a train as they should, and not send me to the poorhouse paying repair bills in the process.

Overall Trip Stats