The w/m injection nozzle coupling worked it’s way loose somehow. I discovered it after dumping about 3 gallons of juice on the road between the time that started and when I identified the problem. So while I was at it I decided to upgrade it to a 2-stage system. The trucks use progressive controllers to modulate delivery, but I really doubt the efficacy of those devices in normal use. The main purpose for having it on the “D” is keeping the intake clean. It can also add a little power. I theorized a more practical approach would be two injection events, a smaller nozzle coming on earlier more often, and a bigger nozzle coming in only at or near full load.

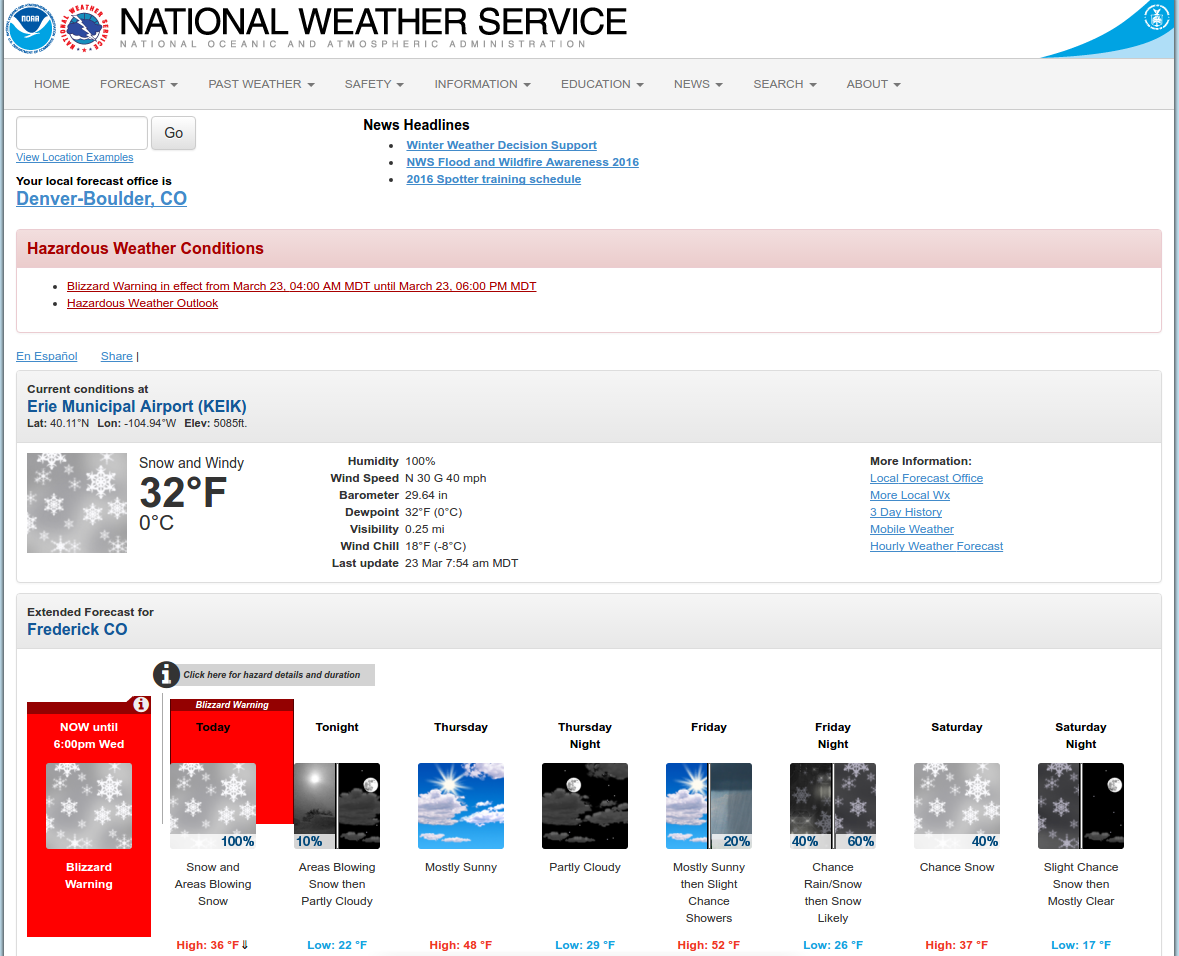

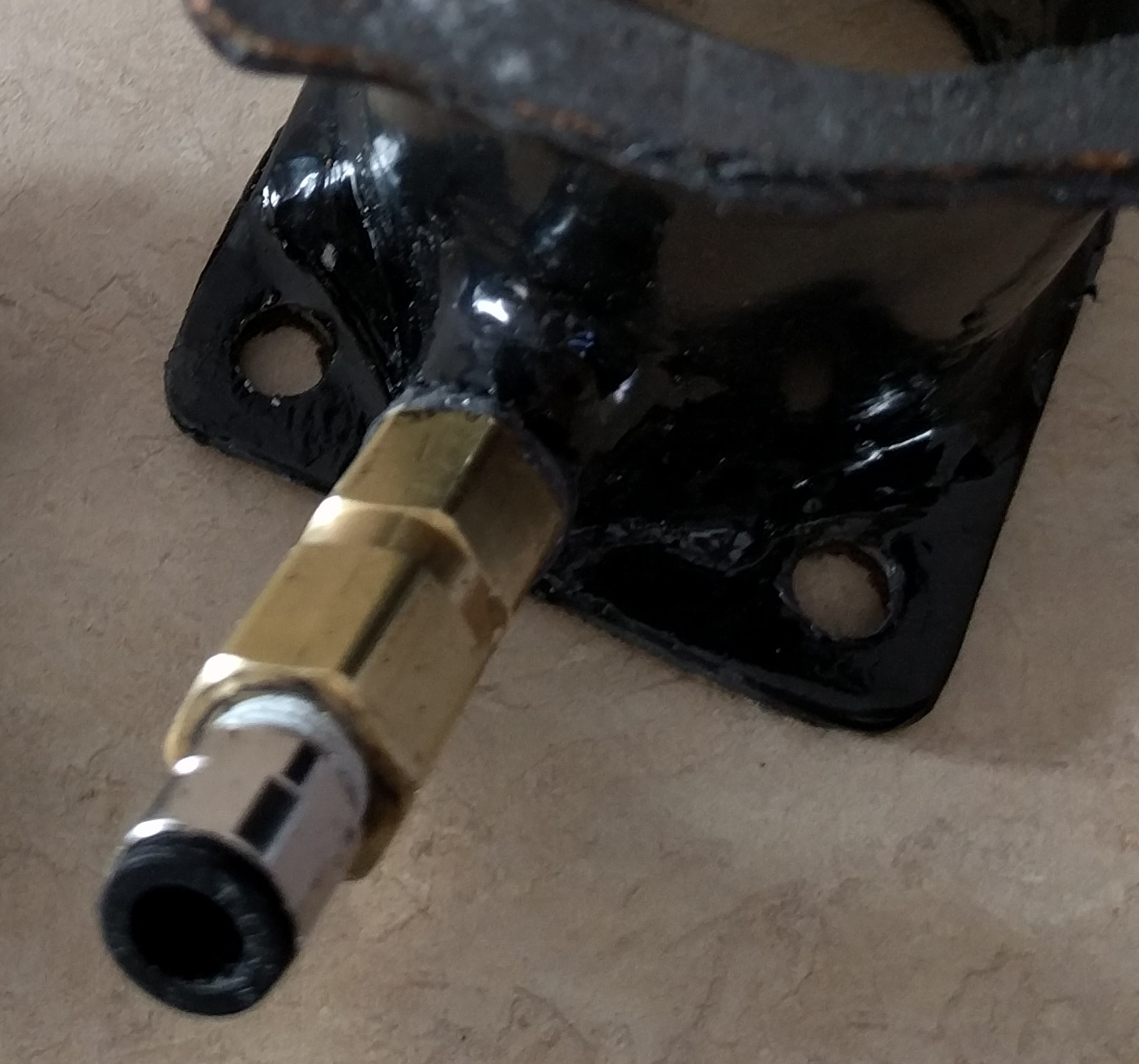

1st phase of the project was installing a 2nd smaller injector, size M2. The original M3 stays put in the intercooler coupler, after of course modifying the connection to keep it secure. I suppose those push-in 1/4″ pipe couplers are OK, because I never had this problem until now, after years of using them on the trucks and continuing to use them at various locations in this system as well. A hose barb reinforced with JB Weld is not coming apart without a forcefully applied tool. Here’s the new nozzle mounted right at the manifold flange:

Phase 2 involved setting up a solenoid valve to fire the original M3 injector off a secondary pressure switch set for the max boost range starting ~24psi. I began by testing with the spare pump to ensure it would effectively atomize 2 injectors, because it’s a pretty small pump. No worries there. Setting the boost switches accurately was a frustrating moving target at first. The engine will see somewhere around a 3psi delta on the high side parameter depending on a number of factors. 22psi is where it typically tops out, but I’ve seen it pull 25 briefly under heavy load.

I used 1-amp fuses on the pump and solenoid circuits to dial it in pretty close to my target settings. Those switches from McMaster Carr are quite sensitive and accurate. I started with them set high and repeatedly ran the car to the desired boost setting, stopped and checked the fuse until it blew. Took three tries on the high switch and about 6 or 7 on the low switch. I haven’t run it with a boost gauge installed since removing Burger’s JBD tuner last summer, but I imagine it should go higher with that extra fuel.

After a couple weeks of using too much water while randomly fiddling with the switch settings I ended up making a tool for pressurizing the system manually to see exactly where the switches were tripping. It probably would be better to tap into the MAF sensor for this purpose, but I’m still a little skittish about the electronics on this high-tech Teutonic contraption.

The pump supply line tees off to the primary injector before the secondary solenoid valve:

The last phase was simply getting everything wired up, plumbed and tested: Pressure Switches:

The air, or “boost side” of the system literally comes together on the driver’s side shock tower. Both switches and the gauge reference the same charge pipe feed at this junction:

The car has a Boost Gauge mounted in the instrument cluster. It’s more of a testing tool that anything else, necessary to fine tune the pressure switches. I used the high-pressure gauge on my compressor to set the switch before, but it’s not good enough at lower pressure to see the 1-psi increments needed for this application with any accuracy.

Compared to the single-nozzle version which came on at 20psi, the system now provides >60% more water/meth on the top end, while delivering about 30% less at moderate load between 18 and 24psi boost. I expect the real-life consumption rate to go up spraying less more often, based on my driving habits. Before I was using about about 1gal/tank of fuel, really only hitting it with go pedal down hard. I’m hoping this new setup equates to better cleaning in normal driving.