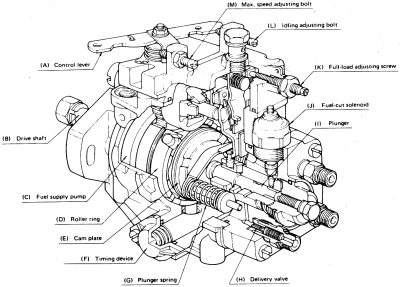

FIGURE 1: Cutaway of VE injection pump showing component location.

(Courtesy of General Motors Corporation Product Service Training)

From: An Introduction to Compact and Automotive Diesels | Edward Ralbovsky

The Robert Bosch

VE-Type

Distributor Pump

Identifying the Robert Bosch VE-Type injection pump

The Robert Bosch VE-type injection pump is used on a variety of vehicles and is made under licenses by other manufacturers (Diesel Kiki and Nippondenso). The Bosch VE pump is primarily found on compact and automotive diesel engines. The code designation on the side of the pump is read:

| Example: NP-VE x/x F xxxx A R NP xx | |

| NP | These two letters stand for the manufacturer, in this case, Diesel Kiki |

| VE | Distributor-type injexction pump |

| x | number of cylinders |

| x | plunger diameter in millimeters |

| F | mechanical governor |

| xxxx | governor-controlled RPM number |

| A | design symbol |

| R | direction of rotation (R for clockwise, L for counterclockwise) |

| NP xx | production serial number |

Main Components

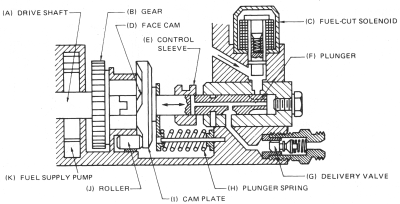

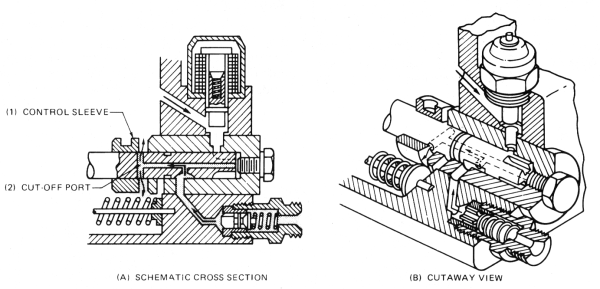

It is necessary to become familiar with the main components of the VE-type injection pump to understand the basic operating principles. Refer to Figures 1 and 2 for the location of the main components.

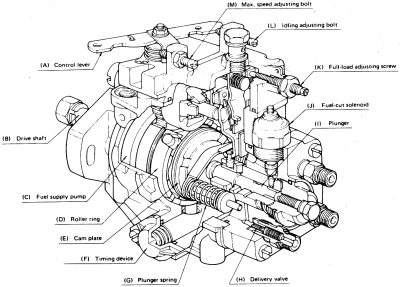

A VE pump may be gear or spur-belt driven. The drive shaft is connected to a cam plate (K) with a driving disk (I), figure 2. The drive shaft, cam plate, and plunger all rotate together. Note the high spots on the cam plate. These high spots are the face cams and the number of face cams equals the number of engine cylinders. As the cam plate rotates, the face cams contact the rollers causing the cam plate and plunger to move back and forth in the plunger bore. Spring pressure holds the cam plate and plunger agains the rollers. The drive shaft also drives the fuel-supply pump (G) and the governor flyweight drive gear (H).

At the bottom of the injection pump is the automatic advance-timing device. As fuel-supply pump presure increases the piston moves the roller ring opposite to driveshaft rotation, advancing injection timing. Mounted outside the distributor head is a delivery valve (N) for each cylinder, fuel-cut (fuel shutoff) solenoid, and an air-bleed screw in the center.

At the top of the injection pum is a control lever (C), a control-lever shaft (D), and an overflow (retun fuel) valve. Engine idle RPM and maximum speed can be adjusted by the idle-speed adjusting bolt and maximum-speed adjusting bolt.

Under the top cover is the governor mechanism.

FIGURE 1: Cutaway of VE injection pump showing component location.

(Courtesy of General Motors Corporation Product Service Training)

FIGURE 2: Cutaway of VE injection pump

(Courtesy of General Motors Corporation Product Service Training)

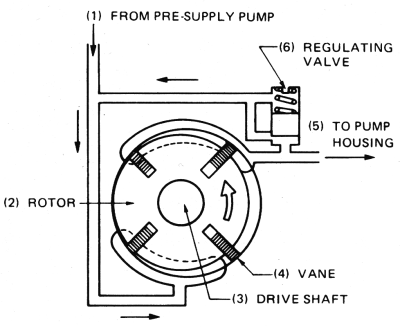

Fuel-Supply Pump

At the driveshaft end of the injection pump is a positive displacement, vane-type fuel-supply pump, Figure 3. It (sometimes with an additional outside-supply pump) is used to bring fuel from the tank and send pressurized fuel to the distributor plunger and the injection timing advance mechanism. Excess fuel is used to cool and lubricate the injection pump.

FIGURE 3: Fuel flow through supply pump

(Courtesy of General Motors Corporate Product Service Training)

Notice that the inside diameter of the supply-pump housing is eccentric (offset) to the center of the rotor. As the rotor turns, the volume between the vane segments changes. Where volume increases is the suction (inlet) side. Where volume decreases is the pressurized (outlet) side.

Supply pump output volume and pressure increase as pump speed increases. Since displacement and pressure of the transfer pump can exceen injection requirements, some of the fuel is recirculated to the inlet side of the supply pump by a regulating valve.

Starting from the bottom, as the pump rotates the volume increases between the vanes. The increasing volume draws fuel into the supply pump. As the rotor continues to turn, a vane will uncover the outlet port. Notice that the volume between the vanes is decreasing, pressurizing the fuel. This pressurized fuel is then governed by the regulating valve.

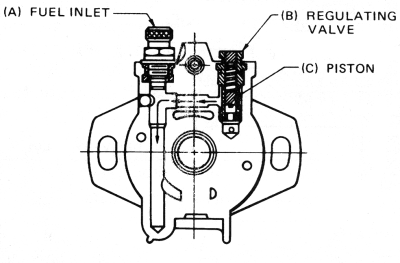

Regulating Valve Operation

Fuel from the outlet of the supply pump forces the piston (C) back, compressing the regulating spring, Figure 4. As fuel flow from the supply pump increases, the piston is pushed further back allowing more fuel to be bypassed back to the inlet side. The speed of the supply pump and regulating-valve-spring pressure determine how much fuel will be bypassed. It is important that the supplyu pump provide the correct pressure for the timing advance and fuel feed for the distributer plunger.

FIGURE 4: Regulating valve

(Courtesy of General Motors Corporation Product Service Training)

Plunger Operation

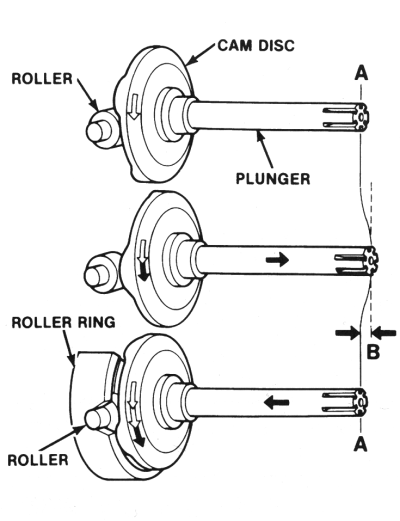

To understand how this pump pressurizes and distributes fuel one must be aware that the plunger has two motions: simultaneously reciprocating and revolving, Figures 5 and 6. As the high spots move off the rollers, pressurization stops as the plunger reverses, allowing fuel to be drwn in for the next stroke. It is the reciprocating motion that pressurizes the fuel and the rotating motion of the planger that distributes it.

FIGURE 5: Plunger, head, and cam-plate assembly

(Courtesy of General Motors Corporation Product Service Training)

FIGURE 6: It is important to understand that the plunger reciprocates

and rotates at the same time

(Courtesy of Ford Motor Company)

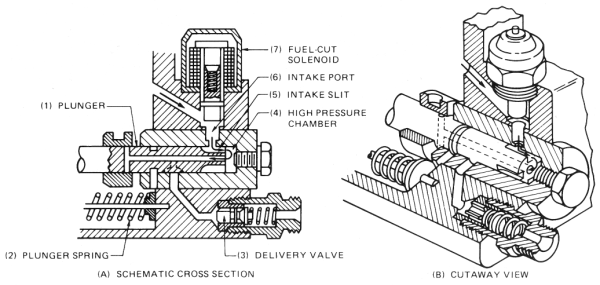

Intake Stroke

When the intake slit (opening) on the plunger, Figure 7, aligns with the intake port during the plunger intake stroke, fuel pressurized by the fuel-supply pump flows into the high-pressure chamber. The number of intake slits equals the number of cylinders.

FIGURE 7: Intake Stroke

(Courtesy of General Motors Corporation Product Service Training)

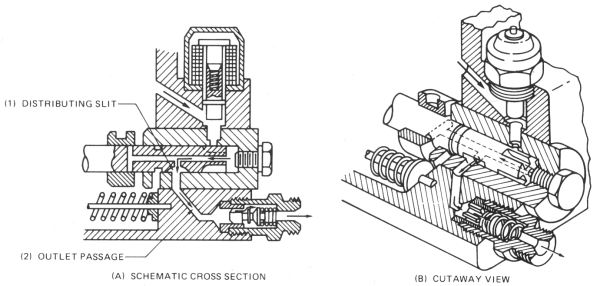

Injection Stroke

Plunger rotation moves the intake slit out of alignment with the intake port and aligns the distributing slit with the outlet passage, figure 8. With the intake port closed, fuel is trapped in the high-pressure chamber. The plnger is also moving into its bore, pressurizing the fuel. The pressurized fuel pushes the delivery valve off its seat and fuel is injected into the combustion chamber of the engine through the nozzle.

FIGURE 8: Beginning of injection stroke

(Courtesy of General Motors Corporation Product Service Training)

End of Delivery

As the plunger continues moving into the bore, Figure 9, the cutoff port moves past the control sleeve. The high-pressure fuel escapes into the pump housing, reduces the pressure, and ends fuel delivery to the injection nozzle.

FIGURE 9: End of delivery

(Courtesy of General Motors Corporation Product Service Training)

Equalizing Stroke

The equalizing stroke occurs as the plunger continues to rotate after the end of the delivery, Figure 10, an equalizing slit 180 degrees opposite the distributing slit aligns with an outlet passage. This causes the pressure in the passage to the delivery valve to be restored to the feed pressure. This insures that all outlet passages have the same pressure to maintain smooth engine performance.

FIGURE 10: Equalizing Stroke

(Courtesy of General Motors Corporation Product Service Training)

Reverse-Rotation Prevention

It is possible for the diesel engine to start in the reverse (opposite) direction of normal operation. The VE pump does not allow this to happen, Figure 11. If the plunger were to rotate in the reverse direction the intake port would open during the injection stroke, preventing any pressure buildup.

FIGURE 11: Reverse Rotation Prevention

(Courtesy of General Motors Corporation Product Service Training)

Fuel Metering

Fuel is metered by the movement of the control sleeve in relation to the plunger cutoff port, Figure 12. Moving the control sleeve changes the effective stroke. The effective stroke is the period at which fuel is pressurized at injection pressure. The longer fuel is pressurized at injection pressure, the longer the effective stroke. So, the longer the control sleeve covers the cutoff port, the longer the effective stroke, and more fuel is injected. At idle the control sleeve is more to the left, providing a short, effective stroke. As more fuel is needed to meet demand, the control sleeve will move further up the plunger, increasing the effective stroke. Note that the mechanical stroke of the plunger remains the same.

FIGURE 12: Effective Plunger Stroke

(Courtesy of General Motors Corporation Product Service Training)

Delivery Valve

When the plunger pressurizes the fuel, fuel pressure overcomes delivery-valve spring pressure and the residual line pressure and pushes the delivery valve off its seat, Figure 13 part A. When pressure drops and injection ends, the pressure in the injection line and spring pressure move the delivery valve and piston, Figure 13 part B. The piston first closes off the injection line. The period from when the piston closes the injection line until the delivery valve seats is called the retraction stroke. This creates more volume, which decreases pressure in the injection line. The retraction stroke prevents cavitation and unwanted secondary injection by dampening high-pressure waves.

FIGURE 13: Delivery-valve Action

(Courtesy of General Motors Corporation Product Service Training)

Governor

A variable-speed governor and a minimum/maximum (min-max) governor are available with this pump, depending on application. Figures 14 and 15 show the parts of a min-max governor. Like all mechanical governors, there is balance crated between spring tension and force generated by flyweights. As flyweight RPM increases, force on the levers increases. These forces, plus the setting determined by the operator, determin the position of the control sleeve, Figure 16.

FIGURE 22: Speed-timer operation

(Courtesy of General Motors Corporation Product Service Training)

FIGURE 22: Speed-timer operation

(Courtesy of General Motors Corporation Product Service Training)

FIGURE 22: Speed-timer operation

(Courtesy of General Motors Corporation Product Service Training)

Starting

During starting, Figure 17, the flyweights are at rest and the starting spring has moved the starting lever and control sleeve for the maximum effective stroke. This will supply enogh fuel to start the engine. When the engine starts, the flyweights move out, compressing the starting spring and shortening the effective stroke.

FIGURE 22: Speed-timer operation

(Courtesy of General Motors Corporation Product Service Training)

Idling

During idle, with the control lever in the idle position, the start-idling spring and the starting spring are in balance with the force from the flyweights, Figure 18, and the control sleeve has moved, reducing the effective stroke during starting. If idle speed drops, spring pressure will move the control sleeve, increasing the effective stroke. If idle speed increases, the flyweights will move the control sleeve to reduce the effective stroke.

FIGURE 22: Speed-timer operation

(Courtesy of General Motors Corporation Product Service Training)

Partial Loading

When the control lever is moved off idle by the operator, by cable through a lever or by accelerator pedal, more fuel is needed, Figure 19. Essentially, this action compresses the damper spring, moving the control sleeve and increasing the effective stroke.

FIGURE 22: Speed-timer operation

(Courtesy of General Motors Corporation Product Service Training)

Full-Load Maximum Speed

The control lever is in the full-load maximum-speed position when it touches the external maximum-speed stop bolt, Figure 20. The springs opposing the flyweights are commperssed, moving the control sleeve and providing the largest effective stoke except for starting.

No-Load Maximum Speed

If the engine speed exceeds the full-load maximum speed, the flyweights now exert enough force to move the control sleever, reducing the effective stroke and preventing fuel from being injected into the cylinder, Figure 21.

Injection-timing Advance

At the bottom of the injection pump is the automatic-advance timing device. As fuel-supply pump pressure increases, the piston moves the roller ring opposite to drive shaft rotation, advancing injection timing, Figure 22. As engine speed increases, fuel pressure from the vne pump also increases. This allows the timer piston to overcome thetimer spring, causing the roller housing to move opposite cam-plate rotation. The rollers then engage the cam-plate high points earlier, advancing injection timing.

Cold-Start Device - CSD (Manual)

The cold-start device advances injection timing at idle and during low-speed running. A lever turns a cam that pushes the hydraulic piston to the left, advancing injection timing about five degrees, Figure 23. This injection advance provides more time for the fuel to burn, which improves performance and prevents smoking during cold starts and warm-up.

The cold-start cam does not advance the complete range of injection timing. Above 2200 RPM the piston operates normally and does not contact the cam.

FIGURE 22: Speed-timer operation

(Courtesy of General Motors Corporation Product Service Training)

FIGURE 23: Manual cold-start advance lever

(Courtesy of Volkswagen of America Inc.)

Cold-Start Device - CSD (Automatic)

There are different types of automatic CSDs available for the VE injection pump. One popular type is the vacuum-operated CSD that uses a vacuum pump, water thermo valve, and a dual-stage diaphragm located on the injection pump, Figure 24. The thermo valve, Figure 25, applies vacuum to the diaphragm(s), depending on coolant temperature. (Figure 26 shows which diaphragms have vacuum applied at various temperatures.)

Another CSD, called the KSB (a Bosch designation), advances injection timing by controlling supply-pump pressure. A KSB control valvemounted on the side of the pump overrides the pressure regulator, increasing supply-pump pressure and advancing injection timing. For example, if the temperature is below the set value of the temperature switch, the switch closes and the KSB solenoid switches on. This increses pump pressure. Above a preset value, the temperature switch opens, the KSB solenoid opens, and the pressure regulator now controls supply-pump pressure.

FIGURE 24: Vacuum-operated CSD

(Courtesy of Ford Motor Company)

FIGURE 25: Thermo Valve

(Courtesy of Ford Motor Company)

| THERMO VALVE TEMPERATURE | DIAPHRAGM FUNCTION | TIMING ADVANCE |

|---|---|---|

| Below 45°F (7°C) |

Stage 1 + Stage 2 | 8 degrees |

| 45-68°F (7-20°C) |

Stage 1 | 5 degrees |

| Above 68°F (20°C) |

None | None (= TDC) |

FIGURE 26: CSD diaphragm operation

(Courtesy of Ford Motor Company)

Aneroid Compensator

The VE-Type pump can be equipped with an aneroid compensator to lower emissions, Figure 27. The aneroid compensator, mounted on the top of the VE pump, modifies the fuel control to adjust for changes in altitude. As altitude increases, atmospheric pressure decreases. This allows the bellows to expand, pushing the adjusting rod downward. This motion is carried through the pin, lever, and tension lever to the control sleeve. The control sleeve is moved toward the drive-end, decreasing the effective stroke.

FIGURE 27: Aneroid compensator

(Courtesy of General Motors Corporation Product Service Training)

Air Fuel Controll (AFC) Valve

The AFC valve (also called a boost-pressure-enrichment device) is added to the fuel-injection pump on engines equipped with a turbocharger. As the turbocharger adds more air to the cylinders, more fuel must be supplied. In Figure 28, note the position of the diaphragm, diaphragm push-rod, bell crank, and control ring. As boost pressure increases, the diaphragm is forced downward, changing the position of the bell crank, Figure 29. The control sleeve (ring) moves further to the right, increasing the effective (working) stroke and the amount of fuel that is injected into the cylinder.

FIGURE 28: Boost pressure enrichment device

(Courtesy o Volkswagon of America, Inc.)

FIGURE 29: Diaphragm pushed downward by boost pressure, increasing

effective stroke

(Courtesy of Volkswagen of America, Inc.)

Fuel-Cut Solenoid

The fuel-cut solenoid, controlled by the ignition switch, Figure 30, opens or closes the fuel-intake passage to the fuel-cut solenoid valve, the intake passage is open, allowing fuel to enter the high-pressure chamber. With no current to the solenoid, the spring-loaded valve closes off the intake port preventing fuel flow. Some VE pumps may have a manual shutdown lever mounted on the side, in case the fuel-cut does not shut off the engine.

FIGURE 30: Fuel-cutoff solenoid operation

(Courtesy of General Motors Corporation Product Service Training)

Servicing The VE Injection Pump

As with other injection pumps, certain precautions hold true for the VE injection pump. Breifly stated, they are:

This pump is used by several engine manufactures and the injection pump is built by manufacturers under license from Robert Bosch. Always consult the service manual specific to the equipment or vehicle you are working on. It will state what pump service procedures and adjustments can be made in the field.

The following procedures are meant only as a guide to explain the procedures. Use the detailed service procedures given in the service manual.

Pump Removal and Installation

This task requires the following

Removal. Carefully clean and wipe the injection pump and surrounding area.

CAUTION: Mark the injection pump mounting flange to the timing case or bracket. This will help preserve injection pump timing.

If the injection pump is belt driven, remove the belt cover.

CAUTION: Mark the belt to the injection pump gear, camshaft gear, and crankshaft gear. This will help ensure that all components are timed properly.

Disconnect the throttle linkage and fuel cutoff solenoid wore. Identify, disconnect, and remove the fuel injection lines. Cap all exposed openings.

Disconnect the remaining fuel lines and remove the injection pump from the pump gear. (Special tools may be required to perform this task. Be careful not to drop any parts inside the timing case.) Remove the injection pump's attaching nuts and bolts to remove the pump.

Instalation. Attach the pump to the engine and line up the timing marks. Tighten the attaching nuts and bolts. Connect the injection pump to the pump gear and connect all fuel lines and injection lines. Then install the throttle linkage and fuel cutoff solenoid wire (check the throttle linkage to be sure it does not bind or stick).

Be sure that all timing marks are lined up, attach the timing belt and adjust tension. Bleed air from the injection pump according to manufacturer's instructions.

Idle Speed Adjustment

This task requires the following:

Since the VE pump is used by several engine manufacturers, there are different methods and tachometers used to set idle speed. It may be necessary to use the magnetic probe-type, or the vibration sensor-type to measure engine RPM.

Before starting the idle speed adjustments, prepare the vehicle according to manufacturer's instructions. This usually means with the engine fully warmed up and all accessories off.

Check Idle Speed. To adjust idle speed, loosen the idle speed lock nut and turn the idle-speed bolt to achieve the desired reading, Figure 33. Tighten the locking nut and recheck idle speed.

High Speed Adjustment

This task requires the same tools used in setting idle speed. (Be sure the manufacturer states that this adjustment can be done; otherwise, do not do it.)

CAUTION: Be certain the vehicle has the parking brake set and the wheels blocked. Make sure all accessories are off.

With the tachometer connected and the engine at operating temperature, briefly accelerate the engine to full-load position and note the tachometer reading. If necessary, adjust the high-speed screw to manufacturer's specifications (see Figure 34). Do not exceed the specified speed or engine damage could result.

Adjusting the Throttle Position Sensor (TPS)

A TPS is used by some manufacturers to control emissions and/or automatic transmission shift points. If the TPS has moved or has been taken off, it must be checked and adjusted as necessary.

This task requires the following:

Connect the DVOM as shown in the service manual. Typically, you will be asked to measure TPS-signal voltage. If the voltage signal is out of range, adjust theTPS as outlined in the shop manual.

Injection Pump Timing

This task requires the following:

VE injection pump timing is performed with the engine off. Despite the fact that it is used by several engine manufacturers, the timing process is basically the same. What must be measured is the amount of injection pump plunger travel at a specific point (usually engine TDC), Figure 35.

Prepare the vehicle according to the service manual. Check to be sure valve timing and timing belt tension are properly set. Remove the screw plug in the hydraulic head and mount the static timing adaptor in the pump, Figure 36. Rotate the crankshaft to the specified reading, then rotate the crankshaft (usually counterclockwise) until the dial indicator stops moving. Zero gauge the pointer and rotate the crankshaft clockwise to the specified position and note the dial indicator reading, Figure 37. (The reading should be withing specifications. If it is less than specified, timing is retarded. Greater than specified, timing is advanced.)

If it is necessary to adjust the timing, loosen the pump mounting nuts (bolts) and rotate the pump to the desired reading. Tighten the nuts (bolts) and check timing. Be sure to remove special tools and replace the screw plug. install any other components removed. Check the idle speed and adjust if necessary.

Summary

The Robert Bosch VE injection pump, made by a variety of manufacturers under license, is primarily found on small, high-speed diesel engines. It can be tailored to meet specific engine needs.

This pump uses a single plunger that rotates and reciprocates simultaneously. The amount of fuel injected is determined by the effective stroke of the plunger. Care is needed when performing service on this pump. Do only the service stated by the manufacturer.